Product Application

As artificial intelligence (AI) rapidly advances worldwide, IT manufacturers are continually releasing new generations of CPUs and GPUs to meet the growing demand for various computational requirements and AI computing capacity. While these advancements enhance data availability and real-time data processing, they also introduce new challenges for data centers, particularly the cooling capacity and energy efficiency.

Traditional air cooling methods used in data center, such as fan systems or Computer Room Air Conditioner (CRAC), can dissipate around 300W to 800W of heat, resulting in a higher Power Usage Effectiveness (PUE)* value of approximately 2. However, with the development of advanced platforms, Thermal Design Power (TDP)* has risen to the range of 700W to 2700W, which results in higher operating temperatures for CPUs and GPUs. This elevated heat output can lead to overheating, performance degradation, and potential malfunctions, rendering traditional air cooling methods insufficient.

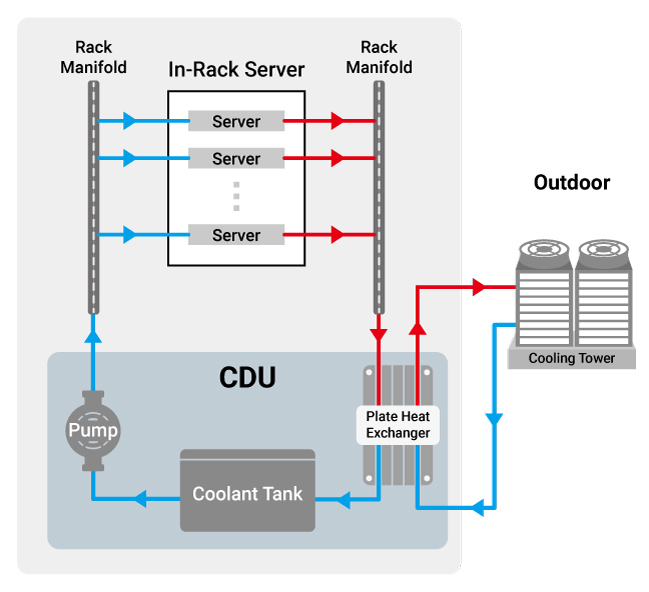

Liquid cooling has emerged as an effective solution for data centers with increased power density, achieving a lower PUE close to 1 for enhanced energy efficiency. There are two primary types of liquid cooling: Direct Liquid Cooling and Immersion Cooling. In a liquid cooling system, a Coolant Distribution Unit (CDU) or Reservoir and Pumping Unit (RPU), which consists of pumps, heat exchangers, a coolant tank, valves, controllers, and critical sensors, plays a crucial role in heat removal and transfer. The CDU monitors key coolant parameters such as temperature and pressure to regulate and circulate coolant or water in a closed-loop system within the server rack and chassis, efficiently removing heat from IT equipment.

*Power Usage Efficiency (PUE): PUE is the ratio of the total facility energy to the IT equipment energy used in a data center. Ex. PUE 1.5 means that for every unit of energy used by the IT equipment, 1.5 units of energy are consumed by the entire data center. This implies that 50% of the energy is used for non-IT purposes, such as cooling, lighting, and other overhead costs.

* Thermal Design Power (TDP): TDP is the maximum heat (in watts) a computer or a device like CPU or GPU generates. The cooling system should be designed to dissipate under the workload.

To ensure efficient heat removal and operational safety, the liquid loop requires the installation of critical sensors, including pressure and temperature sensors. These sensors are strategically installed at critical locations, such as before and after the pumps, as well as at the liquid inlets and outlets, allowing the CDU to adjust optimal fluid flow based on the real-time data provided by the sensors. The pressure sensor enables consistent coolant flow within the liquid loop, preventing potential blockages that could compromise cooling efficiency or lead to overheating. The temperature sensor monitors the coolant temperature, enabling the CDU to regulate temperature and fluid flow effectively.

THINKING offers a range of pressure and temperature sensing solutions to meet the specific requirements of liquid cooling system used in data center. These two sensing functions are available in the following configurations for design flexibility: standalone pressure sensor, combined pressure and temperature sensor, and standalone temperature sensor. All sensing solutions can be housed in stainless steel enclosures, ensuring compatibility with the coolant media commonly used in data center cooling systems.

Pressure Sensor / Pressure and Temperature Integrated Sensor

THINKING's pressure sensor delivers accurate and reliable pressure measurements. It features capacitive ceramic sensing technology and Application Specific Integrated Circuit (ASIC) signal conditioning, which calibrates and compensates the measured data to ensure the correct output signal is transmitted. Building upon the same pressure sensing technology, the dual sensing solution integrates both pressure and temperature measurement functions in a single housing, combining an NTC thermistor with the pressure sensor to provide a compact and robust dual-monitoring solution. This two-in-one sensor enables precise flow regulation in the CDU and reduces the number of components required in the liquid cooling system.

Features

- Robust construction design

- Various pressure port fittings (male): M12 x 1.25, M10 x 1.0, 3/8”-24 UNF-2A, G1/4” thread (Thread sizes are customizable)

- Choices of gauge and absolute pressure measurement types

- Pressure range: 0 bar to 20 bar (up to 40 bar)

- Operating temperature range: -40°C to +125°C

- Electric output signal: Analog, 0.5V to 4.5V

- Accuracy-static 5Vdc: ±0.5% FS

- The pressure and temperature integrated sensor

- Pressure and temperature measurements in one compact package

- The resistance rating, resistance tolerance, and R/T characteristics of NTC thermistor are customizable

THINKING has developed a comprehensive range of immersion-type NTC temperature sensors suitable for direct contact with flowing fluid. The temperature sensors can meet various installation requirements while sharing the same benefits of accurate temperature detection, corrosion resistance, and long-term stability. Modifications are available for these existing temperature sensor packages, including case materials, connectors, lead wires, and O-rings.

(a) The fast-response NTC temperature sensor has an integral connector and a G 1/8'' thread for screw-in installation.

(b) The small-diameter sensing top design optimizes the response time of the NTC temperature sensor. Its NTC thermistor is assembled in a 316 stainless steel housing with a G 1/4'' thread.

(c) The NTC temperature sensor comes with a push-fit mounting design, which offers an alternative to the screw-in installation.

(d) With the bullet-like, stepped-tip mechanical design, the NTC temperature sensor responds relatively fast (< 2 seconds). It can be customized with various mounting features, such as a nut or a clip, to best fit your mounting requirements.

(e) The cylindrical stainless steel probe provides installation flexibility, allowing you to incorporate your choice of mounting components.

Known for its precision, accuracy, and exceptional stability, the platinum (Pt) temperature sensor can be customized with a Pt100 or Pt1000 chip housed in a sealed stainless steel case, with or without threads, to suit your specific application needs.

With customizable options and robust construction, THINKING's pressure and temperature sensing solutions are designed to meet the demanding requirements of advanced liquid cooling system for data center. Including pressure and temperature sensor design early in your product concept phase enables our sensor design engineering teams to leverage their expertise, optimizing sensor integration into your design.

Ready to get started? Tell us about your project and the design considerations of the sensors!

.png)

.png)

.png)

.png)